Scientist turned CO2 into valuable carbon nanofibers with a process that can mitigate climate change.

Halibutboy Flatfish stashed this in Infrastructure

Stashed in: Ecology!, Science!, Awesome, MIT TR, Climate Change, Ecology, Oasis, Nanotechnology, Freakonomics, Nanotech!, Climate Change!

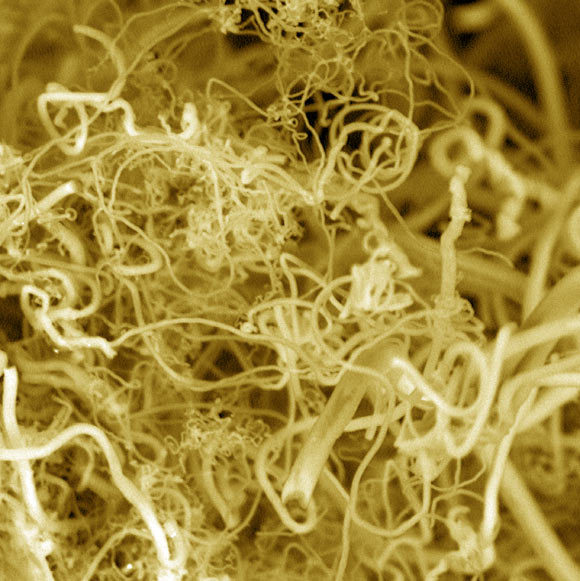

Carbon nanofibers are used to make light but strong things like the Dreamliner, expensive bicycles, and skis.

Cool.

Even cooler: The process is a viable solution to mitigate climate change.

"We calculate that with a physical area less than 10 percent the size of the Sahara Desert, our process could remove enough CO2 to decrease atmospheric levels to those of the pre-industrial revolution within 10 years."

This could be a solution to global warming?! Bold claim!

Through this electrochemical process, CO2 would shift from being a global-warming problem to a feedstock for manufacturing in-demand carbon nanofibers.

“Such nanofibers are used to make strong carbon composites, such as those used in the Boeing Dreamliner, as well as in high-end sports equipment, wind turbine blades, and a host of other products,” said Licht in the statement.

MIT Technology Review points out that currently there is not much market for carbon nanofibers, and Gizmodo website explains that this is no surprise given that at the moment making carbon nanofibers “costs 30 to 100 times more” than making aluminum.

But the cost shouldn’t be an issue for Licht’s team. The process is supposed be low-energy, run by “using only a few volts of electricity, sunlight and a whole lot of carbon dioxide.”

Licht estimates electrical energy costs of this process would be around $1,000 per ton of carbon nanofiber product. That means the cost of running the system is hundreds of times less than the value of product output.

More at MIT Technology Review:

Seems legit. A few Reddit comments:

https://reddit.com/r/Futurology/comments/3htowd/researcher_demonstrates_how_to_suck_carbon_from/

9:40 PM Aug 20 2015